Six reasons why the 100S should be your next core alignment splicer

From increased productivity to enhanced durability, discover why the 100S is the most relevant choice for your next fusion splicer.

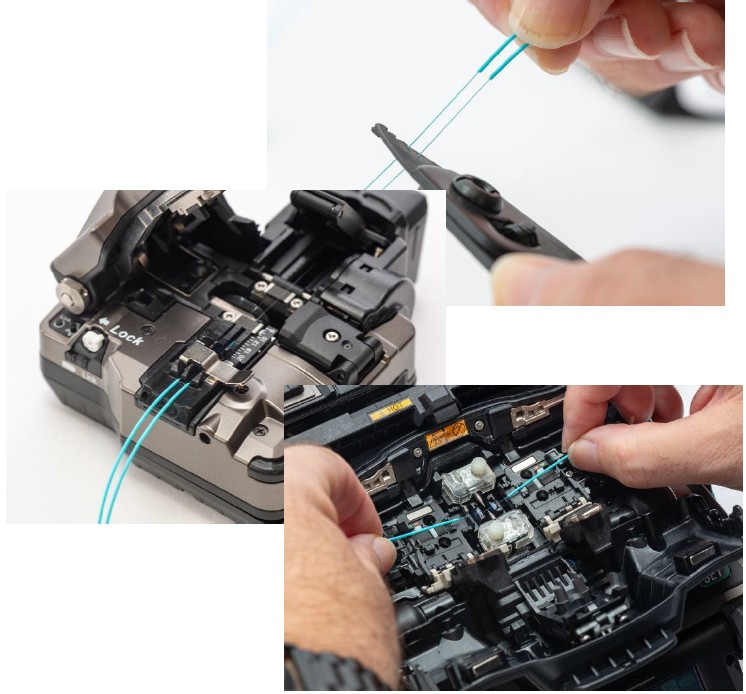

1. Simultaneous fiber preparation for increased productivityThe 100S enhances your workflow with simultaneous fiber preparation. Strip two fibers at once, perform parallel cleaving with a single press on the CT60 cleaver, then place them into the splicer in one smooth motion. An intuitive process that saves you valuable time with every splice. |

|

|

2. Designed to withstand field conditionsBuilt to last, the 100S features six-face impact protection thanks to its structure combining precision-machined metal and reinforced thermoplastic. Drops, impacts, or intensive field use - the 100S is engineered to endure. |

3. Perfect splice repeatability with minimal lossReworking splices is costly and frustrating. The 100S integrates Active Fusion Control (AFC) and Active Blade Management (ABM) technologies. AFC automatically adjusts fusion parameters for stable, low-loss results, while ABM ensures optimal cleaving by rotating the blade when necessary. |

|

|

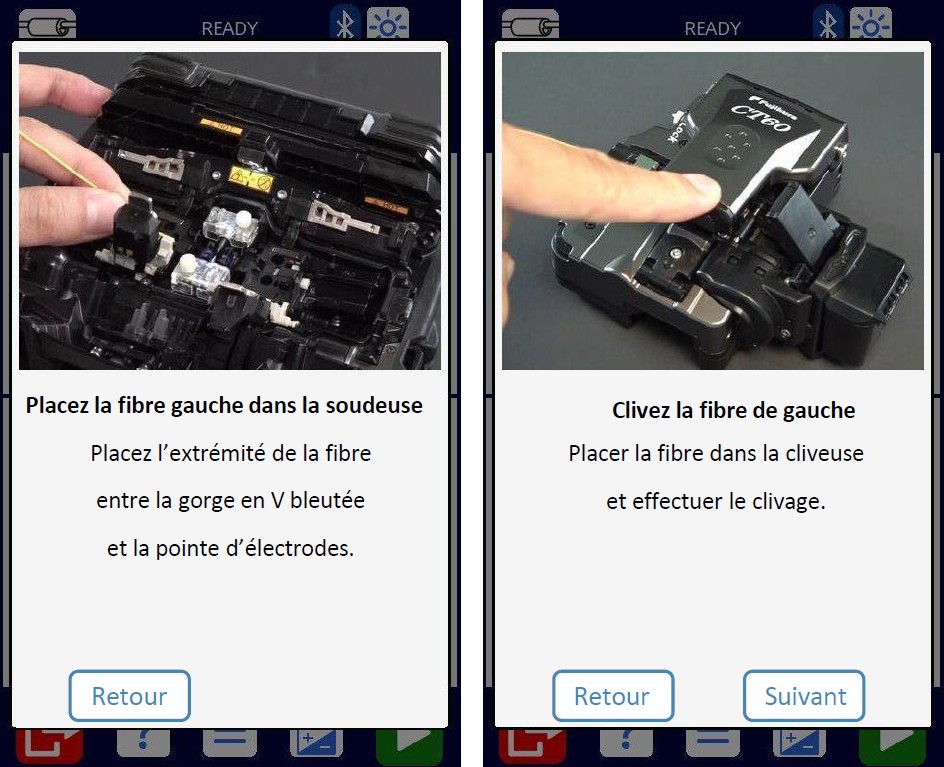

4. Splice Coach: On-screen guidanceSplice Coach provides detailed, step-by-step on-screen instructions throughout the process. It’s like having an expert by your side, ensuring perfect splices every time. |

5. Versatile, durable, and field-readyThe 100S adapts to your workflow: customizable automation functions, a rotatable LCD touchscreen visible even in bright sunlight, and a multifunction carrying case that doubles as a modular workstation. It can even be recharged via a USB-C external battery - perfect for on-site operations. |

|

|

6. Integrated GPS moduleData logging: GPS location information is automatically recorded at the time of splicing. Security: Define a specific area and usage radius - the splicer locks automatically if moved outside the permitted zone. |